The World of car tuning can sometimes be one where facts are warped and twisted in order to suit a particular view point, typically either by an owner who is convinced their modifications are the best or by a supplier looking to promote a particular product or service. It is simple human nature to defend ones decisions and simple business practice to defend ones products, however when it gets to a situation where the bullshit eclipses simple fact then there has to be a point where someone says stop.

When Thorney Motorsport first aquired our own Corsa VXR fordevelopment we went through our usual procedure of development for ECUremapping, running the car in, dyno runs, road runs, track testing etc andfollowing our extensive work with theVX220 race cars we then spent a large amount of time investigatinganalyzing and testing injectors, so as part of all our development now wemeasure how injectors are performing at all levels of power and changing themas necessary.

The process by which an engine generates power is relativelysimple, it simply combines air with fuel and ignites it via a spark within aconfined space in order to move a series of pistons to generate drive via acrank – the art is combing the right amount of fuel with the right amount ofair and timing the combustion to generate the maximum amount of expansion withthe minimum amount of heat.

Air is sucked into the engine via a series of inlets whichvary in design and nature, and this airflow varies massively depending onwhether the car is moving or not, for this reason simply running a car on adyno will not replicate conditions on the road, this is especially important ifthe dyno cell does not have adequate enough airflow via its fan set up, its notjust about keeping the engine cool, its about trying to replicate on the roadconditions – impossible; but important to try.

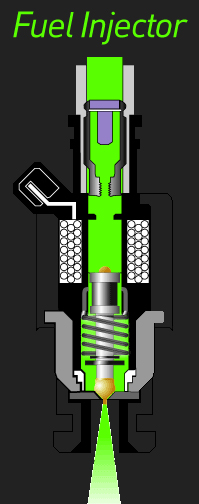

Fuel is controlled by the ECU via a fuel pump, a fuel railand lastly a set of injectors – one per cylinder. To accurately measure a fuelingsystem you need to understand what pressure the fuel pump is generating, thelevel pressure the fuel rail is maintaining (as fuel pump output pressure willfluctuate depending on accelerator position) and finally you need to know howfar open the injectors are – fully open means no more fuel can be sent through.

Measuring a fuel pump output is relatively simple, firstlythere is the stated pressure capacity on the unit itself and secondly you caninstall a guage to accurately measure actual pressure. Measuring maintainedpressure at the fuel rail can be measured in much the same way either in situewith a guage or on a flow bench. A variety of methods can be used to measure aninjectors function, firstly the manufacturer will state in cc’s or grams perminute the maximum capacity of the injector but the only sure fire method is toplace the injector on a flow bench and literally pump liquid through it on ameasured cycle, injectors are sophisticated items but bottom line they are atube with a hole in it and a hole can only flow a maximum amount of fluidthrough it.

Measuring a fuel pump output is relatively simple, firstlythere is the stated pressure capacity on the unit itself and secondly you caninstall a guage to accurately measure actual pressure. Measuring maintainedpressure at the fuel rail can be measured in much the same way either in situewith a guage or on a flow bench. A variety of methods can be used to measure aninjectors function, firstly the manufacturer will state in cc’s or grams perminute the maximum capacity of the injector but the only sure fire method is toplace the injector on a flow bench and literally pump liquid through it on ameasured cycle, injectors are sophisticated items but bottom line they are atube with a hole in it and a hole can only flow a maximum amount of fluidthrough it.

To generate more power from an engine we adjustthe parameters of fuel, air and spark timing to create a bigger explosion inthe cylinder, with a forced induction engine such as the Corsa VXR item, this alsomeans the adjustment of boost to control fuel level, it’s a lot morecomplicated than that of course but this is keeping things simple.

The issue of correct air/fuel mix is the holy grail ofengine tuning, getting it wrong usually means a systemic failure of some kind and there are two ways toget it wrong. Firstly, if you don’t have enough air in the mixture the enginewill run ‘rich’ – too much fuel. This can lead to unburnt fuelremoving valuable lubricant from the engine internals known as bore wash. Typicallywe err on the side of too rich for all engine tuning as bore wash only occursat very high levels of imbalance and the process of using fuel aids enginecooling which is safer for all engines.

Secondly, you can have too much airin the mixture. This will cause the engine to run lean – too much air/toolittle fuel. This is the equivalent of garlic to a vampire – it’s bad.If too little fuel is used in combustion then the explosion itselfessentially is too hot (again, simplified) as the presence of fuel has acooling effect. Think of it like an explosion on TV, to get the right effectthe director wants a nice combination of explosive effect, flame and smoke, toomuch fuel in the mix and he’ll get a nice flame but the explosion will be lessdramatic, too little fuel in the mix and he’ll get a big explosion but thedamage will be more severe.

If an engine is running lean then the internal temperaturesbecome too high and damage is the result, typically this is manifested inpiston crown damage where it heats up too much and breaks down.

Thorney Motorsport is unique in being the only Vauxhalltuning company to be an authorized Vauxhall outlet, ie this means that we hearof information through other dealers, GM themselves and the grapevine more thansome others and during the course of last year we heard of more and morefailures of Corsa VXR engines. The damage reported was consistent – number 4piston failure leading to varying levels of engine failure. Over the last 6months we personally have inspected 9 Corsa VXR engines with engine failure andon every single one the failure was on the number 4 piston. On every singlefailure the car had been remappedby a particular tuning company or via one of this company’s hand held ECUremapping devices. There was also another engine failure (again on number 4piston) we inspected that had beenremapped by another tuning company but this company used the same softwaresupplier for their ECU remaps, and this was repaired under its own warranty. Hadall these failures been handled by the tuning company themselves then we (oranyone else) would have had no knowledge of the issue, however the advice beinggiven to the owners of these cars was to ‘put the car back to standard and takeit to a dealer’ and as such these cars were entering the dealership networkwith ‘unexplained’ failures – all on number 4 piston – in other words thedealership network (and TMS) were handed an issue to repair, this is not a caseof trying to score points on a competitor, if the problems had been repaired bythe supplier then it has nothing to do with us, Vauxhall or the dealershipnetwork.

Hang on though we can hear you say, why are you so sure thatit is the mapping of the cars that is causing the problem? The answers:

1. Allthe cars inspected had number 4 piston crown failure

2. Thedamage is consistent with excess heat from the piston running too lean

3. Ninecars were running this particular company’s software and the 10thsoftware from the same supplier

4. Therehave been no reported failures in the UK on standard cars

5. Ourevidence shows that the injectors are exceeding their maximum flow rate whichwould explain the cause of the damage.

This list generates a couple of questions. Firstly how do weknow whose map is on the car? Well in the cases we have actually seen the ownertold us, secondly we have software available that can interrogate a cars ECUand even when the map has been ‘removed’ it leaves enough of a trail that wecan identify what map was on the car. The second question of course is how dowe know the injectors are maxxing out?

Before we go through the process of measuring injectors itsworth going through the lean/rich concept via measuring mixture in the exhaust.The only 100% accurate way to measure the engines overall fuel mix is via theinstallation of a wide band lambda sensor in the exhaust, for development weactually install a special boss in the exhaust system but for customer cars aprobe is placed in the exhaust, most tuners do this. However the results of thewind band sensor have two flaws; firstly all they measure is the overallengines output so if you have a situation where a particular injector isrunning lean before the others a wide band sensor at the exhaust wont detectit. Secondly the measurement of exhaust gases is determined by how much airflowthe engine is receiving and if the dyno cell doesn’t have enough then what maylook fine on the dyno will equal lean when on the open road. Its for thisreason that not only does our dyno cell have the highest airflow in the UK but we alsotest on the road with a wide band lambda sensor attached to the car.

Before we go through the process of measuring injectors itsworth going through the lean/rich concept via measuring mixture in the exhaust.The only 100% accurate way to measure the engines overall fuel mix is via theinstallation of a wide band lambda sensor in the exhaust, for development weactually install a special boss in the exhaust system but for customer cars aprobe is placed in the exhaust, most tuners do this. However the results of thewind band sensor have two flaws; firstly all they measure is the overallengines output so if you have a situation where a particular injector isrunning lean before the others a wide band sensor at the exhaust wont detectit. Secondly the measurement of exhaust gases is determined by how much airflowthe engine is receiving and if the dyno cell doesn’t have enough then what maylook fine on the dyno will equal lean when on the open road. Its for thisreason that not only does our dyno cell have the highest airflow in the UK but we alsotest on the road with a wide band lambda sensor attached to the car.

As already explained the available fuel to an engine iscontrolled by the fuel pump, the fuel rail the injector and ultimately the ECU,the ECU controls the parameters of how much power is required via boostlevel. Now fortunately enough anothercompany has been kind enough to demonstrate that the standard pump and rail isable to generate enough pressure for the standard car and even higher powerlevels, there is a video on youtube (for now):

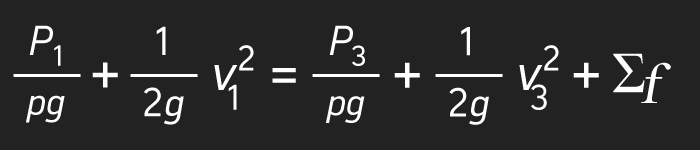

This video shows the fuel pressure being maintained on adyno run. However using the available fuel pressure as a statement that theengine is getting enough fuel into the cylinders whilst relevant is notcomplete enough, at the end of the day the size of the hole in the injector isconstant, it doesn’t matter how much pressure you throw at it it will only beable to flow a maximum amount of fluid and that maximum is determined ultimatelyby its size, this is calculated by the Bernoulli equation which if you areinterested is this:

The available pressure to the injector is only one thing itneeds to flow enough fuel, to actually deliver the fuel needed it needs to belarge enough to flow it, period.

So, we can measure an injector, we can ascertain that thereis enough fuel pressure how do we measure the point at which the injectormaxxes out? An injector is an electronic valve, once energized an electromagnetmoves a plunger that opens a valve that allows fuel to pass through, thisopening and closing of the valve occurs many times per second and this numberof times is controlled by an electronic pulse known as pulse rate, so aninjector is a physical valve opening and closing determined by an electronicpulse controlled by the cars ECU. The simple way to measure such a device iswith an oscilloscope. An oscilloscope is a device that displays a graph of anelectronic signal, they are used by a myriad of industries and have been fordecades importantly they can measure with utmost accuracy the moving parts ofan electronic circuit – an injector.

Now watch this video, it shows a Corsa VXR running a stage 1map (peak power approx 215-220bhp) in the foreground you will see anoscilloscope which shows the electronic output from the injector. At 4900rpm the electronic signal changes, theinjector is fully open and cannot inject any more fuel, from this point thecylinders are demanding more fuel but there is no more to flow, this means thatthe cylinder is progressively running leaner and leaner as more air is suckedinto the chamber, increasing heat and leading to damage. All of this is controlledby the ECU map, the higher the power generated the further down the rev rangethe injectors reach their maximum, standard cars (194bhp) reach their maximumat 5600rpm (approx), 230bhp equates to 4900rpm which is as low as we areprepared to take them, any higher and the rpm level is simply too low to besafe. This explains the advice given from this particular tuner that full powershould not be used for more than 5 seconds or that some people have problemsearlier than others; if you use full throttle more you are likely to run theengine leaner for longer.

In our opinion running a car where the injectors cannot flowany more fuel is not wise, it is acceptable to have this limit at the upperlevels of the cars RPM as at these levels the ability to run the car at maximumRPM for any degree of time is limited but to have this limit any lower than4900rpm is not something we would advocate, to run the car at power over 240bhpwould mean the injectors are maxxing out a good deal lower in the RPM rangethan 4900rpm. For this reason we have developed larger injector maps for ourown upgrades, these allow for 250bhp+ power but injector levels well withintheir maximum.

We are strong advocates of owners knowing as much as theycan about their car and how to modify it, however to go to the extent ofwriting up in such detail is not something we would anticipate undertaking (Ican think of better things to do with my Saturday nights if I’m honest).However we were faced with multiple cars with serious engine failure which wasbeginning to give the Corsa VXR a poor reputation and that’s not good for anyowner. Had the matter been dealt with internally by the supplier then none ofthis need to have come out but if the stated process for repair was to try tocon the dealership network, the customer and anyone else then they only havethemselves to blame, not us.

The Corsa VXR is an excellent engine to tune but as with allupgrades its knowing what can be done is paramount.

Thorney Motorsport on Facebook